Prečišćivači prašine

Prečišćivači prašine

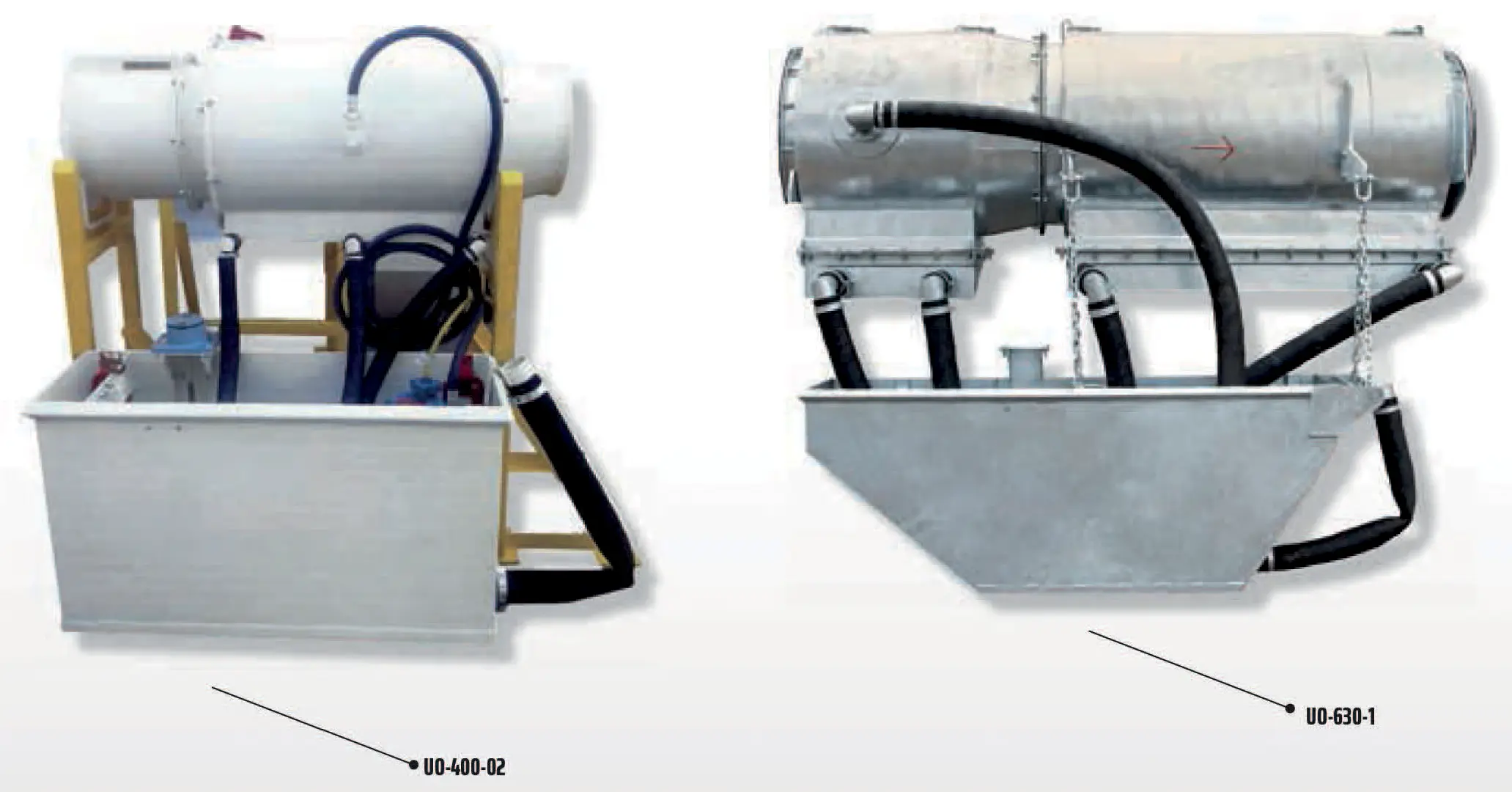

The Dust Collectors type UO are designed lo remove dust from the air flowing through them, especially coal dusts, coal-stone dusts, stone dusts and industrial dusts. Dust is removed by the wet method. The device works in closed-circuit of water. Devices are comply with the requirements of the Directive ATEX and they are devices of group I category M2.

he Dust Collectors type UO are adapted lo work in mines, in which there is methane hazard (excavation with degree of ,,a", ,,b" and ,,c" of methane explosion hazard) and coal dust explosion hazard (excavation with class of ,,A" and ,,B" of coal dust explosion hazard). The Dust Collectors type UO are adapted lo work in mining excavations driving by roadheaders, ventilated by combined or exhaust ventilation. Devices can work as a stationary devices for dedusting chutes, tippers, chambers in the mines and in coal processing plant or can also cooperate with conveyor and coal crusher, as a mobile device. Dust collectors can be used outside of mining, e.g. in coke plants, power plants, heating plants, production facilities which have separate areas with hazard of dust explosion.

VIn the Dust Collector can be apply additional commercial equipments e.g. Whirl Jet, inlet guiding vanes, droplet pre-separator, reduction connectors, connecting elements, bearing elements. II is possible lo change the shape and location of the water lank - under the device or in the place designated by the User.

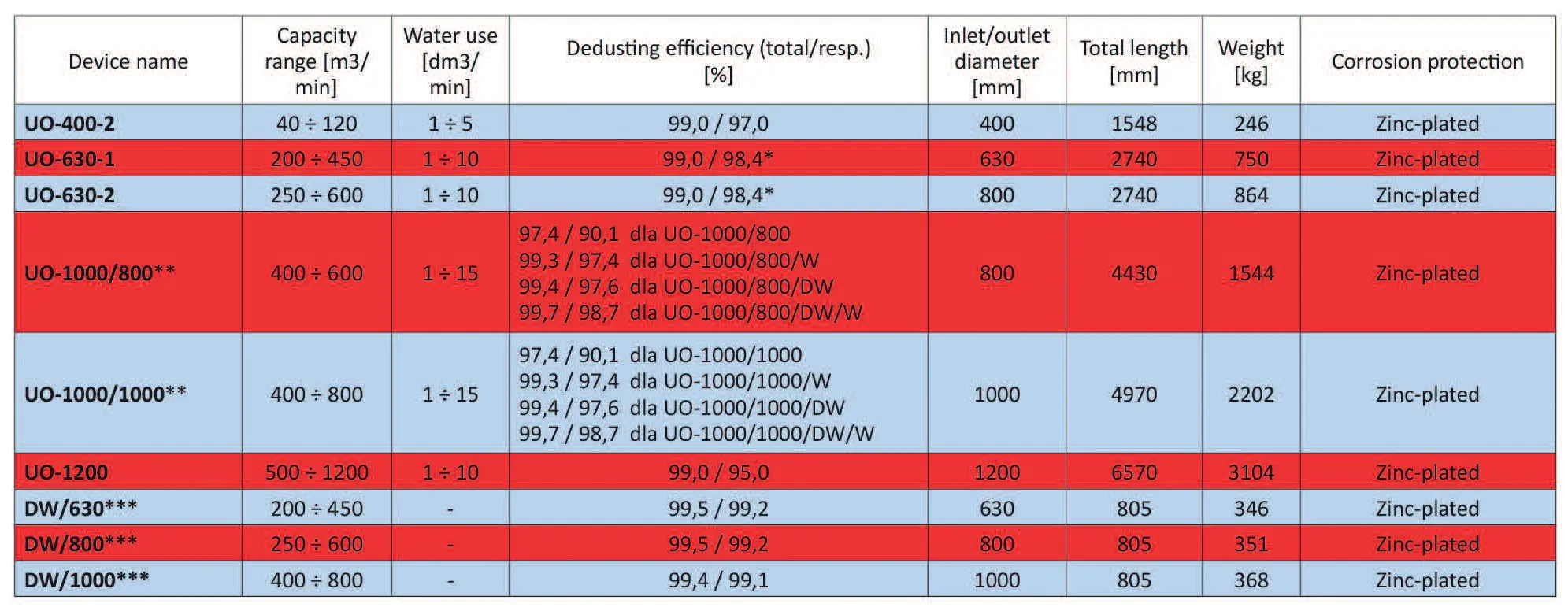

- *Using the Whirl Jet type OW or corrective insert W increase total dedusting efficiency till 99,5% and respirable till 99,2%

- **Executive variant e.g.: W - applied Corrective Insert, OW - applied Whirl Jet

- ***In Whirl Jet was used a switchable motor 500/lDDDV type d50Kg16DL2-P with power 18,5 kW